Heavy-duty connector aviation plug Hot runner

Video

pecifications

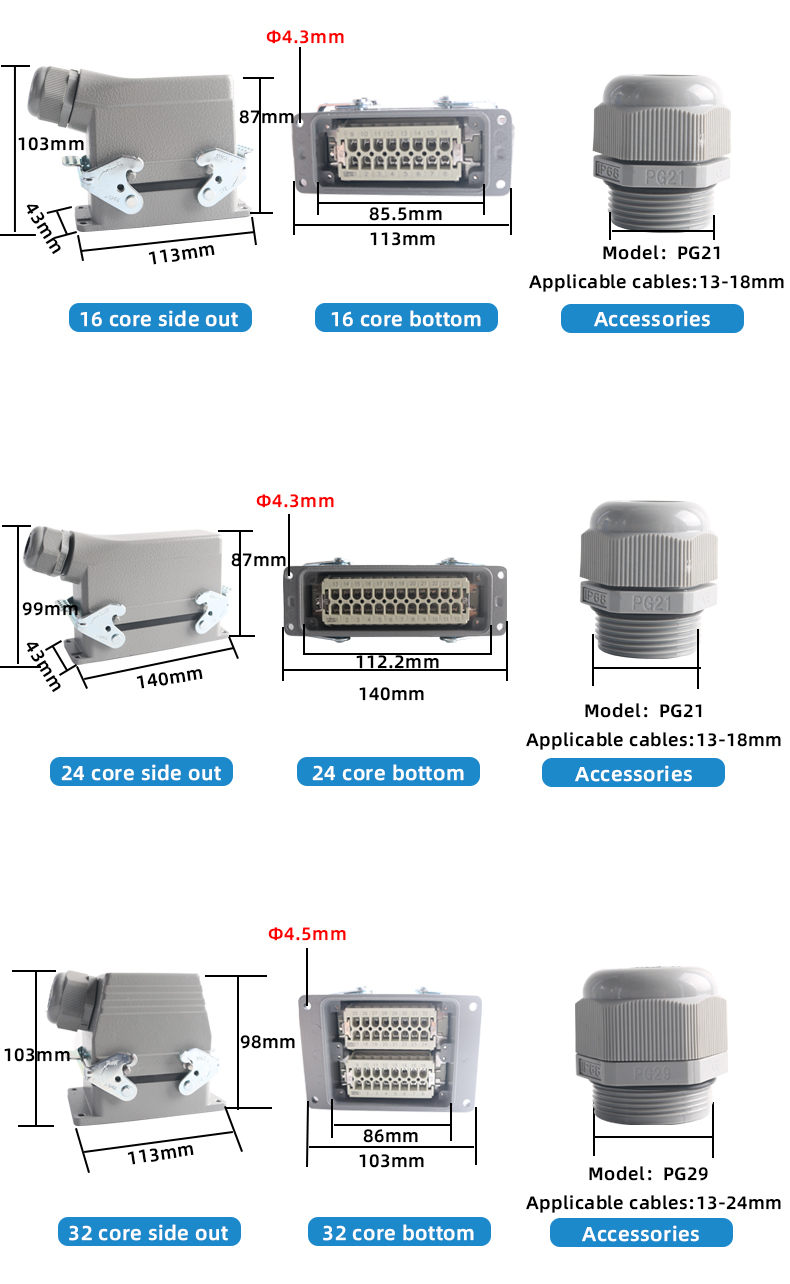

- Model Number: HE24 series

- Rated current: 16A

- Rated voltage: 500V

- Termination methods1: Screw terminal

- Termination methods2: Quick Lock / Cage-clamp terminal

- Termination methods3: Crimp terminal

- Shell Options: Suitable for H B housing

- Number of cores: 24pin

- Limiting temperatures: -40℃ ...+125℃

- Mating cycles: ≥500

description

Heavy-duty connectors are designed to withstand the harshest industrial environments. Traditional connected devices provide users with several years of service guarantees in a typical office environment. However, exposing the same copper or fiber optic connectors to extreme conditions degrades performance and reliability, requiring end users to pay high maintenance costs for troubleshooting and replacement parts. A new connector specifically designed to build a robust Ethernet connection in harsh environments that is tougher, stronger and more resistant than previous connectors.

Heavy-duty connectors, also known as heavy-duty sockets, are widely used in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, electric locomotives, petrochemical electrical equipment, etc. that require electrical and signal connections. The international advanced nature of heavy-duty connectors in structural design and material use makes the connectors outstanding in electrical performance. The reliability of the electrical connection system cannot be achieved by traditional connection methods.

Heavy Duty Connector Advantages

1. Unique design of anti-open circuit mechanism to ensure that it meets the performance test requirements of instantaneous current 100A 5S;

2. There is no interference between the clip insertion of the anti-opening open-circuit mechanism and the gap between the female pins, ensuring more than 2000 times of insertion and extraction;

3. The complete set of products has good sealing performance, and the protection level reaches IP67;

4.The product is locked with a buckle, which has a damping effect and has an anti-drop function.

Three factors that affect the service life of heavy-duty connectors

1. Selection of raw materials: If the product uses inferior raw materials, the quality and service life of the produced products will be greatly reduced.

2. Electroplating protective layer: The metal parts are too thinly plated or poorly plated at the contact plugging and unplugging parts.

3.Adaptability and stability: the male and female mating is not tight enough, and it is not resistant to vibration and waterproof effects.

application

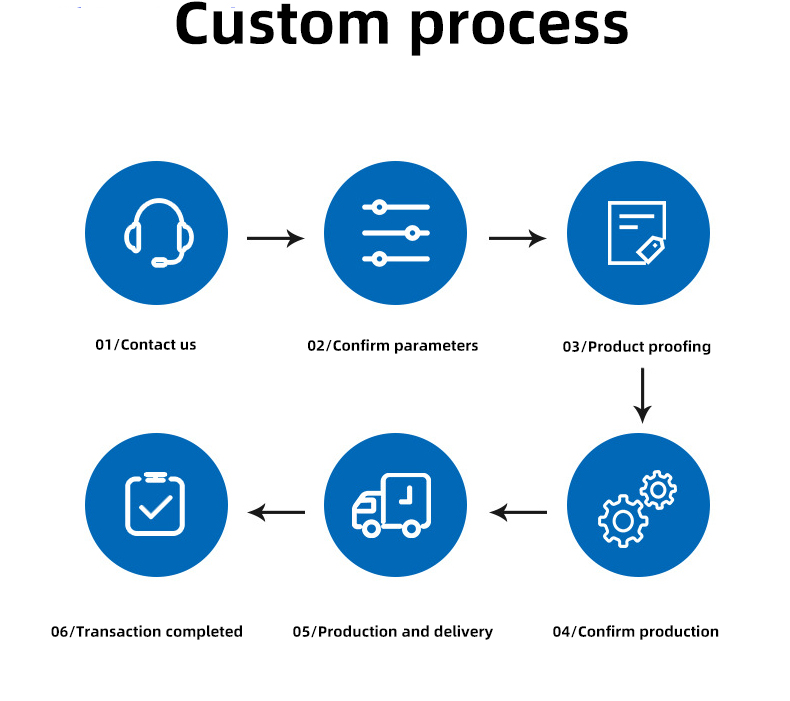

customize

packing

Certificates