Anderson plugs will encounter these situations during use, high temperature, crushing of heavy objects, and beating. These situations are also unavoidable in industrial use. Therefore, high-quality raw materials are the premise to ensure these. If it is made of general materials or recycled materials, these performances cannot be guaranteed. When encountering a fire source and high temperature during use, it will be ignited and burned, and the safety performance cannot be guaranteed, resulting in immeasurable losses. In the event of stepping on, heavy objects squeeze the rubber shell and break, resulting in the machine being unable to connect to the power supply for normal use, causing unnecessary trouble, interrupting work, and causing losses. This is the prerequisite for the safety performance of the Anderson plug. At present, the materials of Anderson plug terminals on the market are generally silver-plated copper, nickel-plated copper, and nickel-plated brass. What is the difference between these terminals?

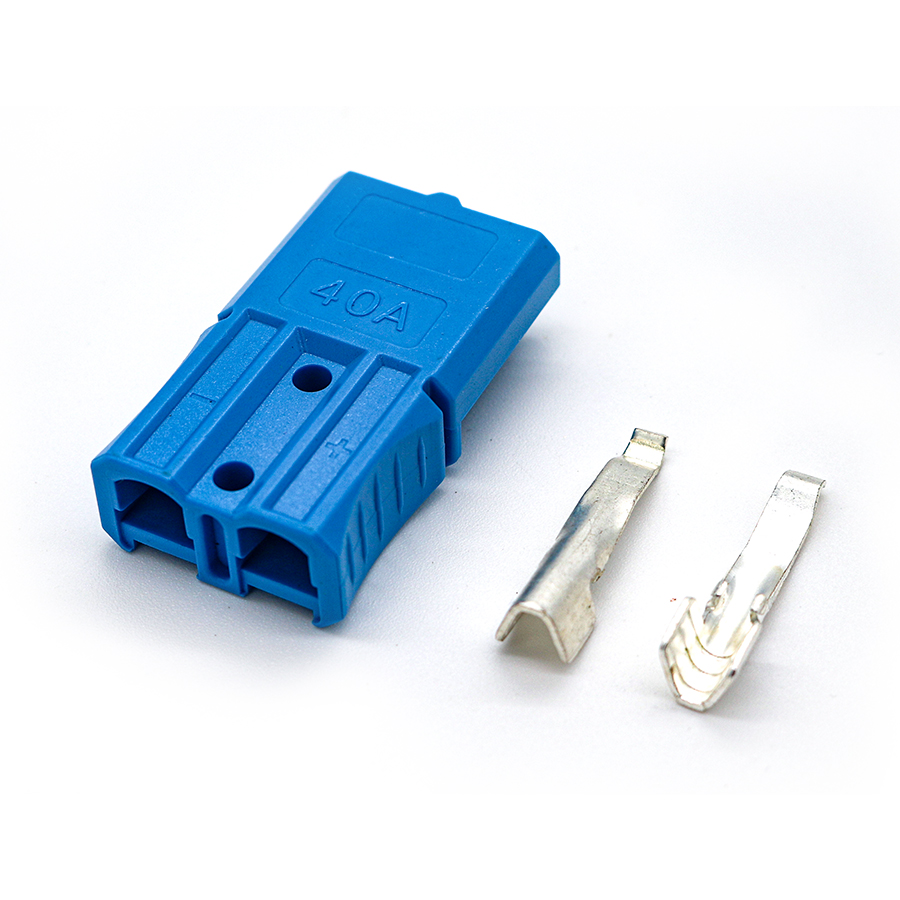

Quenching process: soft and hard application, so that the terminal will not break in the process of crimping and wiring, some people break the crimping terminal during the application process, the reason is here, without quenching treatment, the terminal hardness is too large, it will break when pressed . If the quenching is not well quenched, it will also cause the crimp to break, or the terminal is too soft and easily deformed during use. Plugs are generally divided into plug and socket combinations, but Anderson plugs do not distinguish between plugs and sockets, neither male and female, as long as the same color can be inserted.

At present, there are three main types of Anderson plugs on the market: single-pole plugs, double-pole plugs, and three-pole plugs.

Anderson single-pole plugs are single-terminal plugs, which can be assembled and combined with positive and negative poles. Common specifications are 45A, 75A, 120A, 180A (Abe).

The choice of copper: red copper – excellent conductivity, strong plasticity, not easy to break during crimping, high price

Brass–Poor conductivity, high hardness, easy to break during crimping, low price

Silver: Excellent conductivity, high price

Nickel: poor conductivity, low price

Anderson bipolar plugs are double-terminal positive and negative pins. The same color can be plugged in each other, and there is no male and female distinction. Common specifications are: 50A, 120A, 175A, 350A (Abe)

There are three connection methods for common Anderson plug power connectors.

1. [Highly recommended] Crimping: The crimping connection should enable the wire and the contact to produce metal mutual flow and symmetrical deformation of the material, similar to the cold welding connection, which can obtain better mechanical strength and electrical continuity, and can withstand more harsh environmental conditions. At present, it is generally believed that the correct crimp connection arm should be soldered well, especially in the case of high current, the crimp must be used.

2. [General recommendation] Welding: The most common connection is soldering. The most important thing for a soldered connection is the continuity of the metal between the solder and the surface to be soldered. The most common coatings for connector solder ends are tin alloys, silver and gold.

3. [Not recommended] Winding: Directly wind the wire on the winding post of the contact piece with water chestnut. When winding, the wire is wound under the condition of controlled tension, pressed and fixed at the water chestnut of the winding column of the contact piece to form an airtight contact.

Post time: Nov-22-2022